CORPORATE OFFICE

(818) 492-3500 or

(800) 247-6242

FAX (818)492-3530

ELECTRONIC MAIL Email Us

Email Us

Hand Presses

Manually Operated Dies

Announcing the TIMELY FABRICATION SYSTEM for increased efficiency and profit.

TA-26 M.O.D. Units

This series of manually operated Hand Presses permit you to fabricate prefinished material into fire rated KD sidelites, borrowed lites and transoms. The TA-26 Casing Cut-off, Header Notch, Coping Press, and Glass Stop Cut-off Press are all you need for producing professional sidelite systems at amazingly affordable prices.

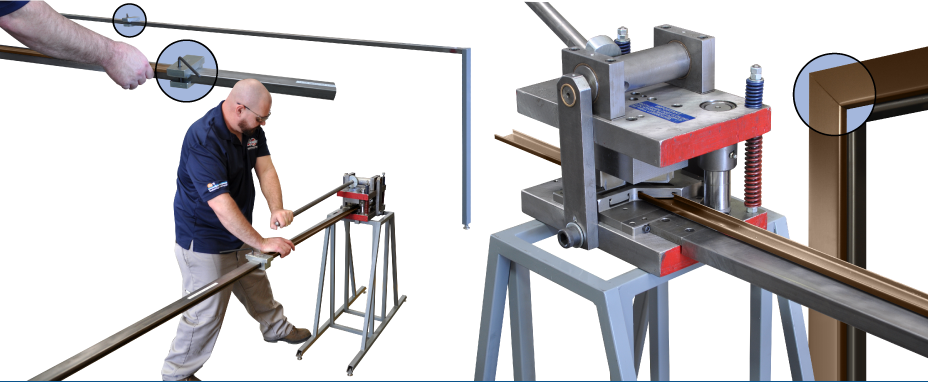

TA-26 MODC Casing Cut-off |

|

|

Provides effortless, precision cuts on TA-8 casing for either left hand or right hand 45 degree miters or 90 degree straight cuts. |

TA-26 MODN Header Notch |

|

|

Used to easily create either a header notch or mullion notch in using three simple operations. Accommodates jamb depths from 3 3/4" up to 8 3/4" (excluding 4" roll formed profile). |

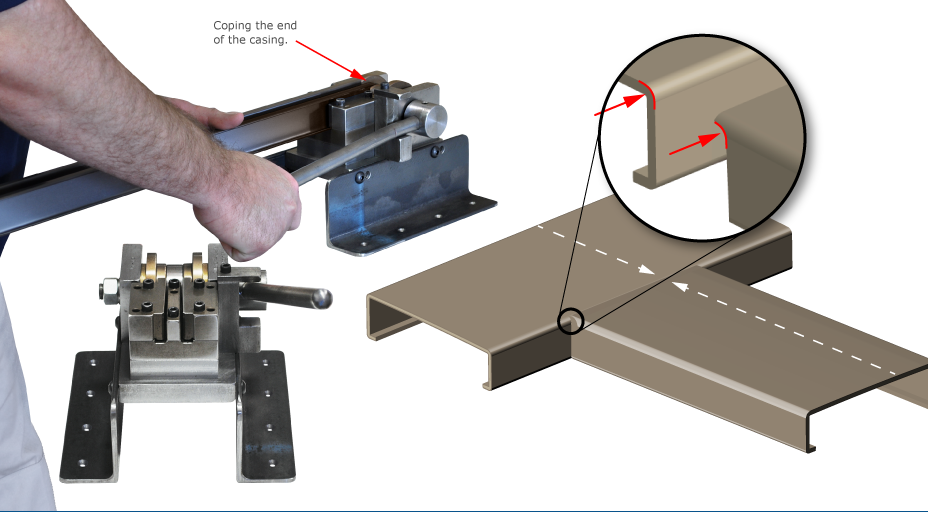

TA-26J Coping Press |

|

|

The Coping Press is used to cope the ends of TA-8 that intersect TA-8 casing at a 90 degree angle. Coping the end of the casing provides a tight fit around the radius formed edges of the casing. |

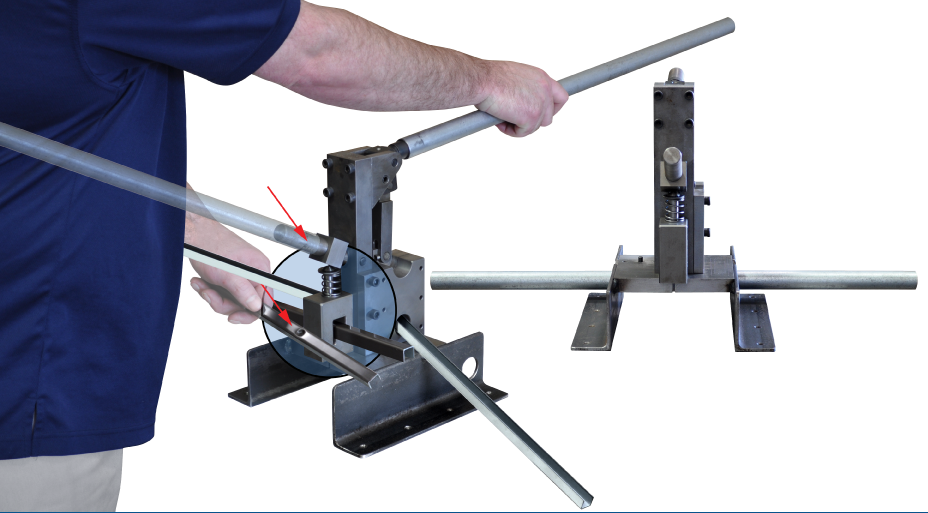

TA-26GS Glass Stop Cut-off Press |

|

|

The Glass Stop Cut-off Press provides precise and effortless cutting of glass stop for sidelights, borrowed lights and transoms. The press has a secondary punch that punches and dimples the glass stop for the glass stop screws . |